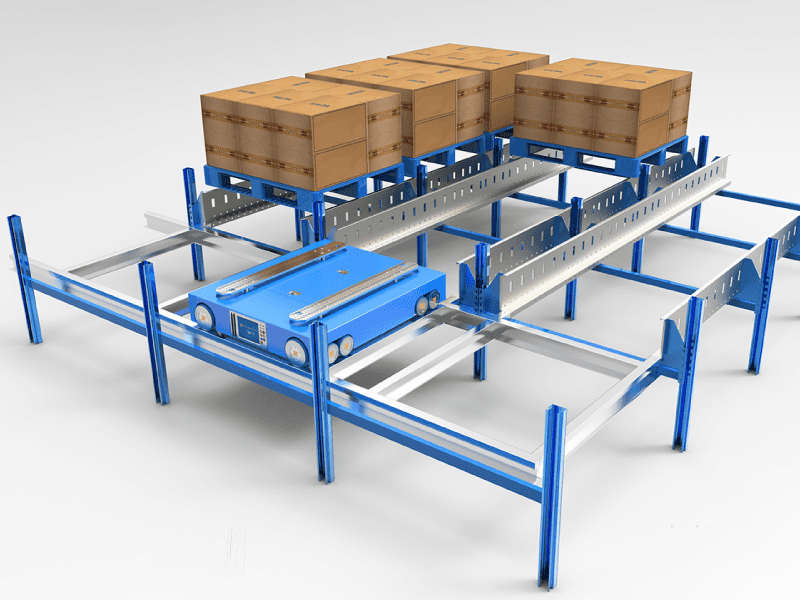

Radio Shuttle Racking System

What is a Radio Shuttle Racking System?

A radio shuttle racking system is an automated device used for warehouse transportation. Its storage density and automation capabilities have revolutionized modern warehouse operations.

How a Radio Shuttle Racking System Works

After receiving inbound and outbound requests, the warehouse management system (WMS) plans the optimal route and generates task instructions. These instructions are transmitted to the shuttle via wireless communication. The radio shuttle racking system travels along rails installed on each storage level, positions itself under a pallet, lifts the pallet, and transports it to the designated storage location, working in conjunction with stacker cranes located between racks. The warehouse control system receives instructions from the WMS and controls the shuttle's movement.

Advantages of a Radio Shuttle Racking System

1. High Efficiency

Multiple shuttles can operate independently at different levels simultaneously, significantly improving operational efficiency.

2. Optimized Storage Space

Radio Shuttle Racking System is controlled by WMS software. Warehouse Management System determines the optimal location for each pallet, minimizing unused storage space.

3. High Security

Advanced control technology ensures smooth and reliable operation, and multiple safety protection measures are in place.

Applications of Radio Shuttle Racking System

1. Cold Storage

Radio shuttle racking systems are widely used in the cold chain industry. First In First Out (FIFO) or Last In First Out (LIFO) inventory management is suitable for fresh foods and fruits, reducing the need for forklifts in extremely cold environments and improving worker working conditions.

2. Beverage Industry

The high density and excellent accessibility of radio shuttle rack system meet the rapid turnover needs of the beverage industry.

3. Pharmaceutical Industry

In the storage of pharmaceuticals with high standardization requirements, radio shuttle rack systems enable rapid sorting and management.

Jiangsu Vison Storage Equipment Ltd. has successfully provided automated storage and retrieval systems (AS/RS) solutions for numerous fresh produce, fruit, and cold storage businesses, resulting in savings of up to 35% on annual management costs. Our professional technical and after-sales team will customize solutions to meet your specific needs.

Do you need more information?

Our team of experts will be happy to help you with any questions you may have.

More information