Real-World Supply Chain Strategies 101

Key Takeaways:

- Create adaptive and targeted supply chain strategies for changing environments

- Master five foundational supply chain strategy types

- Analyze six industry-proven models to inform your operations

- Strengthen operational resilience against market and logistical volatility

- Leverage warehouse planning and technology to amplify throughput, accuracy, and agility

Supply Chain Strategy Redefined

A modern supply chain strategy is more than just a blueprint—it’s a dynamic framework that aligns sourcing, inventory, logistics, and delivery with evolving customer expectations, regulatory standards, and market shifts.

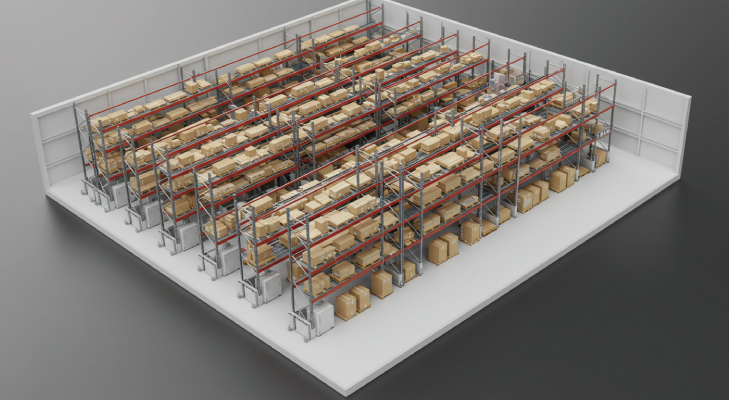

At the core of this strategic framework lies warehouse planning. A warehouse isn't just a stop along the supply chain—it's the operational engine where strategy translates into tangible results.

Essential Supply Chain Strategies

Here are five time-tested strategies that continue to shape global logistics:

1. Lean Strategy

Eliminates all forms of waste. Focused on just-in-time inventory and continuous improvement.

2. Agile Strategy

Designed for responsiveness to change, ideal for volatile or seasonal demand.

3. Customization Strategy

Supports personalized or configure-to-order products using modular warehousing and dynamic picking.

4. Green Strategy

Emphasizes sustainability through energy efficiency, reduced emissions, and responsible sourcing.

5. Global Strategy

Coordinates cross-border logistics, enabling multinational operations with consistency and compliance.

Strategic Alignment: Making the Right Choice

| Factor | Strategic Consideration |

|---|---|

| Business Objectives | Optimizing for speed, cost, sustainability, or innovation |

| Product Lifecycle | Stable, seasonal, or frequently changing |

| Customer Expectations | Speed, customization, traceability, or sustainability |

| Market Volatility | Demand and supply stability, logistics cost sensitivity |

| Digital Maturity | Real-time visibility and coordination capability |

Warehouse Planning: Strategic Backbone of the Supply Chain

Effective warehouse planning maximizes space, speeds fulfillment, and minimizes costs while adapting to growth and disruption.

1. Facility Design and Layout

- Efficient flow from receiving to dispatch

- Strategic slotting based on turnover

- Vertical and mezzanine storage utilization

2. Forecasting and Demand Planning

Use historical, seasonal, and promotional data to plan space and labor effectively.

3. Inventory Strategy

- ABC classification

- Safety stock policies

- Cycle counting

- Demand-based replenishment

4. Labor Optimization

- Skill-based task zoning

- Incentive systems

- Labor forecasting tools

- Automation of repetitive tasks

5. Process Standardization

Document and refine core processes for consistency and scalability.

Warehouse Technology That Drives Strategic Value

1. Warehouse Management Systems (WMS)

Controls inventory, manages slotting, tracks KPIs, and enhances order accuracy.

2. Real-Time Location Systems (RTLS)

Track assets and reduce time spent locating items.

3. Internet of Things (IoT)

Monitor temperature, humidity, and equipment health for sensitive products.

4. Predictive Analytics

Anticipate demand, detect bottlenecks, and optimize inventory levels.

5. Cloud Integration

Seamless coordination across ERP, eCommerce, 3PLs, and transport systems.

Six Battle-Tested Supply Chain Strategy Models

| Company | Strategy Type | Warehouse Role |

|---|---|---|

| Amazon | Agile | Tech-driven fulfillment centers for rapid order processing |

| Walmart | Lean | Cross-docking to minimize storage time |

| Zara | Agile | Central distribution enables fast replenishment cycles |

| Apple | Global | Integrated networks and tight supplier coordination |

| Tesla | Vertical | Local warehousing to reduce supply risk |

| Unilever | Green | Logistics aligned with sustainability goals |

The Threefold Benefit of a Resilient Strategy

1. Adaptability

Build agility to pivot between bulk orders and single-item picks.

2. Risk Management

Prepare for disruption with safety stock, multiple suppliers, and distributed networks.

3. Competitive Advantage

Consistent performance builds trust and loyalty in a competitive landscape.

Integrated Supply Chain Execution: What Sets Leaders Apart

- Centralized Intelligence with Distributed Execution: Global data, local action

- Digital-First Mindset: Real-time dashboards and automated decisions

- Scalable Infrastructure: Flexible systems and modular workflows

- Continuous Improvement Loops: Feedback and data-driven tweaks

FAQ

What’s the most important element of a supply chain strategy?

Alignment. Every aspect of operations must support your chosen strategic direction.

What is the best strategy for unpredictable demand?

Agile strategies allow rapid response to changing customer and market needs.

How do warehouses improve sustainability?

Through smarter energy use, localized distribution, and high fulfillment accuracy.

What role does the warehouse play in eCommerce fulfillment?

It’s the execution center—delivering on promises for speed, accuracy, and efficiency.

Should you centralize or decentralize your warehouse network?

Centralized hubs offer control and scale; decentralized nodes offer speed and service. Hybrid often wins.

Bottom Line

Effective supply chain strategies don’t end at the boardroom—they’re built into the warehouse floor. Whether your business leans toward cost efficiency, adaptability, or sustainability, your warehouse must be designed to reflect—and support—those priorities. With the right planning, systems, and mindset, you won’t just keep pace with change—you’ll lead it.

Do you need more information?

Our team of experts will be happy to help you with any questions you may have.

More information