Mezzanine Floor Racking

Mezzanine Floor Racking System could help you make use of the vertical space of your warehouse in as to double or even triple the usable surface area. It could be one of the most cost-efficient methods to increase your storage locations not at the expense of extra floor space.

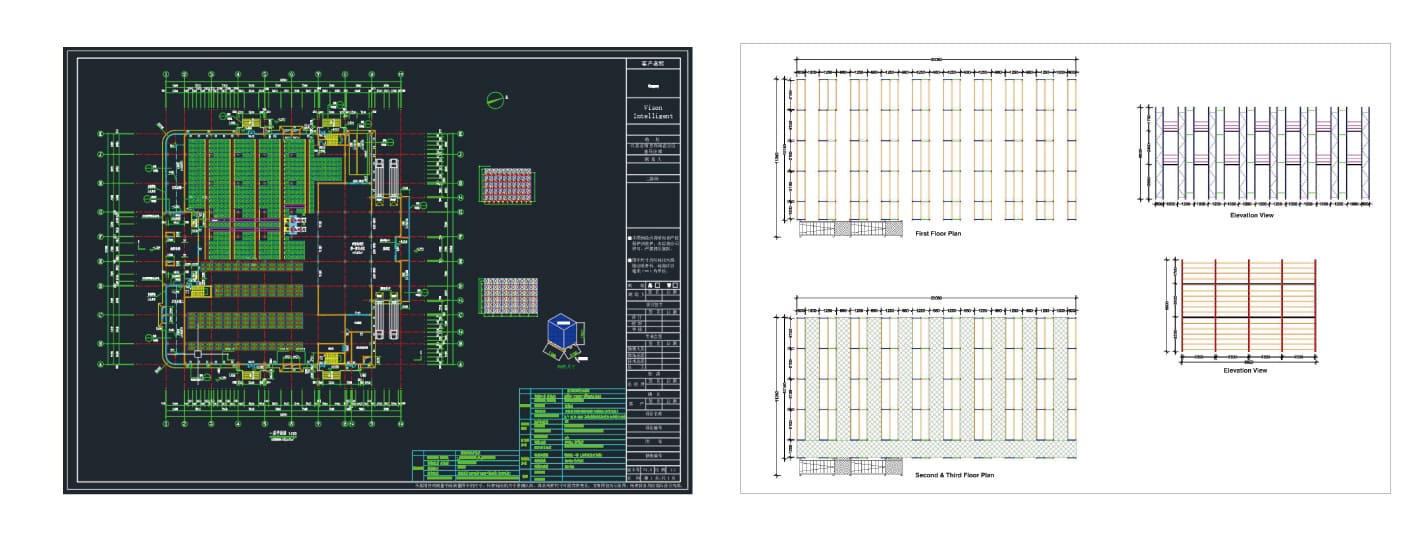

Mezzanine Floor Rack System

Mezzanine floor rack combines a mezzanine structure with shelving or pallet racking below. This two-tier system optimizes vertical space, making it an ideal choice for warehouses and facilities retaining the idea of warehouse expansion or layout improvement.

We could design and manufacture Rack Supported Mezzanine and Steel Structure Mezzanine based on your designated requirements.

Required Information for Mezzanine Floor System Quotation

To prepare an accurate quotation for your Mezzanine Floor system, please kindly provide the following essential information:

-

Warehouse Layout Plan:

AutoCAD drawing or a draft sketch of the warehouse, clearly showing the area where the mezzanine floor will be installed.

Please indicate any existing structures or obstacles (e.g., columns, walls, stairs). -

Warehouse Size and Layout:

Overall length, width, and clear height of the warehouse.

Indicate the available space for mezzanine installation. -

Number of Levels (Tiers):

Please specify how many mezzanine levels you require (e.g., single-tier, two-tier, etc.). -

Shelving or Racking Dimensions (if applicable):

Dimensions of shelving units to be installed on or under the mezzanine (Length × Depth × Height). -

Load Capacity per Mezzanine Level:

Maximum uniform load capacity required per level (e.g., 300 kg/m², 500 kg/m²). -

Floor Load Capacity:

Load-bearing capacity of the existing warehouse floor (kg/m²), to ensure it supports the mezzanine structure safely. -

Preferred RAL Color:

Indicate your preferred RAL color code for the mezzanine structure, guardrails, stairs, and other components (optional).

This structured information will help us deliver a fast, accurate, and tailored quotation for your mezzanine floor solution. If you need assistance in gathering any of these details, our technical team is ready to help.

Key Features

Maximum Space Utilization

Leverage vertical space efficiently with multi-level storage and operational zones.

Cost-Effective Expansion

Budget-friendly alternative to facility relocation with scalable storage solutions.

Enhanced Durability

Cold-rolled steel construction ensures smooth finish, safety and long-term reliability.

Customizable Design

Tailored solutions for retail, warehouse, logistics and manufacturing requirements.

| Specification | Details |

|---|---|

| Load Capacity | 200-1000 Kgs/Square meter |

| Layers of floor | 2-3 layers |

| Floor height | Every 50mm adjustable from bottom to top of uprights |

| Mezzanine Height | 2,000-100,000mm |

| Mezzanine Width | 2,000-100,000mm |

| Upright | 80*50, 100*50, 120*50, 140*50, 160*50; thickness: 1.5-2.0mm |

| Finish | Powder coating (different color acceptable) or hot-dip galvanized as requested |

When was Vison Storage established?

Vison Storage began operations in May 2008, providing innovative storage solutions worldwide.

What is your factory's production capacity?

Our factory has a monthly production capacity of approximately 200,000 tons.

What is your standard delivery time?

Delivery times vary depending on the order details. Generally, we deliver within 25–45 days. For precise timelines, please contact our sales team for tailored advice.

What are your main export products?

Our core product offerings include:

- Selective Racking: Teardrop and traditional models

- Cantilever Racking: Traditional designs

- ASRS Solutions: Radio Shuttle ASRS, Crane-Based ASRS, and Four-Way Shuttle ASRS

- Specialty Racks: Double Deep, Drive-In, VNA

- Mezzanine Structures

- Pallets: Steel, Powder-Coated, Galvanized, and Hot-Dipped Galvanized

- Custom Mechanical Equipment Components

Which countries do you export to?

Vison Storage exports to numerous international markets, including the US, Switzerland, Australia, Denmark, India, the Netherlands, Pakistan, Mauritius, and various Southeast Asian countries like Cambodia, Thailand, Indonesia, Singapore, and Malaysia.

What international trade terms do you offer?

We handle all major international trade terms, including EXW, FOB, and CIF. For detailed information, reach out to us to discuss your specific requirements.

What are your payment terms?

Our standard payment terms are:

- 50% T/T in advance as a deposit

- 50% T/T against a copy of the B/L as the balance

If you require alternative arrangements, our representatives are happy to assist and provide a customized solution based on your needs.

How do you ensure proper packaging of products?

We use packaging tailored to the product type and customer agreement. Options include corrugated paper, carton boxes, crossties, pallets, angle steel, plastic film, steel ties, and airbags. With extensive export experience, we guarantee secure and efficient packaging.

Can I visit your factory?

Absolutely! We welcome visitors to our factory. To arrange a tour, please email us, and our representative will assist you in planning your visit.