What are factors to consider when design a warehouse

Key Takeaways

- Effective warehouse design integrates space utilization, inventory management, material handling systems, and safety protocols for maximum operational efficiency

- Strategic layout planning reduces travel distances and optimizes picking operations, potentially reducing labor costs by 30-40%

- Technological integration through WMS, automation, and data analytics creates measurable improvements in throughput and accuracy

- Future-proof designs incorporate flexibility, sustainability, and scalable technology to adapt to changing market demands

- Proper ergonomics and safety considerations reduce workplace injuries while improving productivity metrics

Introduction

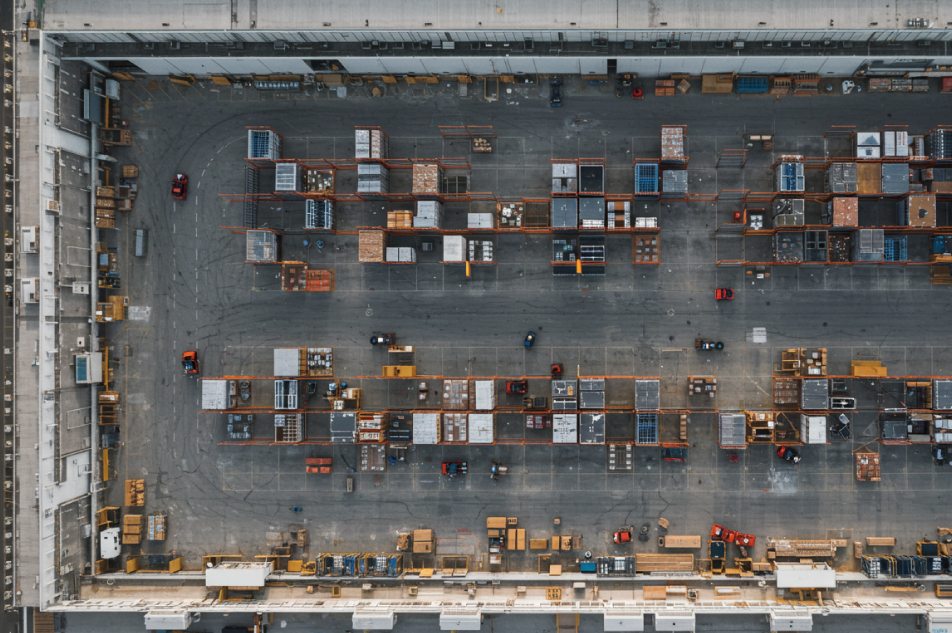

The strategic design of warehouse facilities stands as a cornerstone of modern supply chain excellence. Far more than mere storage spaces, warehouses function as sophisticated operational hubs where efficiency directly impacts bottom-line performance. In today's competitive marketplace, the difference between an optimally designed warehouse and a substandard facility can mean millions in operational costs and significantly influence customer satisfaction metrics.

This comprehensive guide explores the essential factors that logistics professionals must consider when planning and implementing warehouse designs. From fundamental spatial considerations to advanced technological integration, each element plays a crucial role in creating a facility that balances immediate operational needs with long-term strategic objectives. Whether developing a new facility or optimizing an existing operation, understanding these critical design factors provides the foundation for creating warehouses that drive competitive advantage through operational excellence.

Foundational Elements of Warehouse Design

Before examining specific factors, it's vital to recognize that effective warehouse design begins with a thorough analysis of business requirements and operational objectives. This preliminary assessment should encompass:

- Current and projected inventory profiles

- Order characteristics and seasonality patterns

- Throughput requirements

- Customer service expectations

- Budget constraints

- Site-specific limitations

With these parameters established, planners can address the core factors that shape warehouse functionality and performance.

Space Utilization: Maximizing Operational Capacity

The judicious use of available space represents the cornerstone of warehouse design. Beyond simply accommodating inventory, optimal space utilization enhances operational flow, reduces unnecessary movement, and controls facility costs.

Strategic Layout Configuration

Warehouse layout configuration demands a methodical approach aligned with specific business operations. The configuration must balance storage density with operational accessibility—two factors often in opposition. Options include:

Block Stacking – Offers high-density storage for homogeneous products with limited SKU counts. While maximizing space utilization, this method compromises selectivity and may increase product damage risk.

Wide Aisle Configuration – Prioritizes accessibility and picking speed at the cost of storage density. This arrangement proves advantageous for operations with high SKU diversity and frequent picking requirements.

Narrow Aisle Design – Strikes a balance between storage capacity and accessibility, requiring specialized handling equipment but delivering approximately 40% more storage than traditional wide aisle configurations.

Very Narrow Aisle (VNA) – Maximizes storage density while maintaining individual pallet accessibility. This configuration requires specialized equipment and precise operational protocols but can increase storage capacity by up to 50% compared to conventional designs.

The layout should reflect operational priorities—whether emphasizing storage capacity, picking efficiency, or throughput velocity.

Vertical Space Optimization

Underutilized vertical space represents one of the most common inefficiencies in warehouse operations. Effective vertical utilization strategies include:

High-Bay Racking Systems – These configurations can extend 40+ feet high, dramatically increasing storage capacity within the existing footprint. Implementation requires specialized lift equipment and may necessitate enhanced fire protection systems.

Mezzanine Installations – These intermediate floors effectively double usable space for appropriate inventory categories, particularly suited for small parts or slow-moving items.

Multi-Tier Picking Modules – These structures create multiple picking levels accessed by stairs, conveyor systems, or vertical lifts, dramatically increasing picking locations within limited floor space.

Automated Storage and Retrieval Systems (AS/RS) – These systems maximize vertical utilization through computerized retrieval mechanisms that can operate at heights exceeding 100 feet.

When assessing vertical space utilization, designers must consider building specifications including floor load capacity, ceiling height clearances, sprinkler locations, and lighting configurations.

Zoning and Product Placement

Effective warehouse zoning segregates operational areas based on activity type and product characteristics:

Receiving Zones – Dedicated spaces for inbound processing, quality control, and staging before putaway, sized according to receiving volume and inspection requirements.

Storage Zones – Areas allocated for various storage mediums (bulk storage, pallet racking, shelving) organized by product characteristics and movement patterns.

Picking Areas – Zones optimized for order selection, potentially divided into case pick, broken case pick, and specialized handling areas.

Packing and Shipping – Spaces equipped for order consolidation, verification, packing, and staging for outbound transportation.

Value-Added Service Areas – Designated sections for kitting, assembly, customization, or other specialized services.

Strategic zoning reduces travel distances, prevents congestion, and improves operational flow throughout the facility.

Inventory Management: Optimizing Product Flow

Inventory management considerations profoundly influence warehouse design. The storage and handling requirements of inventory directly shape facility layout and equipment selection.

Strategic Slotting Methodologies

Slotting—the strategic placement of products within the warehouse—directly impacts operational efficiency. Effective slotting methodologies include:

Velocity-Based Slotting – Positions fast-moving items in prime locations with easy access and minimal travel distance. This approach can reduce travel time by up to 30% compared to random storage methods.

Complementary Product Placement – Locates frequently co-ordered items in proximity to reduce picking travel and improve order completion rates.

Family Grouping – Organizes similar products together to simplify restocking and inventory management while potentially sacrificing some picking efficiency.

Size and Weight Considerations – Places heavier items at lower levels and positions products based on ergonomic handling requirements to reduce injury risk and improve picking speed.

The slotting strategy should align with order profiles and be regularly reassessed as product movement patterns evolve.

Inventory Control Technologies

Modern warehouse design must accommodate sophisticated inventory control technologies:

Barcode Systems – Still the foundation of most inventory tracking systems, requiring appropriate spacing for scanning operations and label visibility.

RFID Implementation – Radio frequency identification enables non-line-of-sight tracking but requires infrastructure installation including readers, antennas, and network connectivity throughout the facility.

Voice-Directed Systems – These hands-free solutions require appropriate acoustic design considerations and network coverage throughout picking areas.

Pick-to-Light Systems – These visual picking aids require electrical infrastructure and integration with shelving or racking systems.

Warehouse Management Systems – The central nervous system of modern warehouses, requiring server rooms, workstations, and network infrastructure throughout the facility.

The technological infrastructure must be considered early in the design process to ensure proper integration with physical structures and operational processes.

Storage Medium Selection

Different inventory profiles demand appropriate storage solutions:

Selective Pallet Racking – Offers 100% accessibility to all pallets but utilizes space less efficiently than higher-density options.

Drive-In/Drive-Through Racking – Provides high-density storage for homogeneous products with limited SKU diversity.

Push-Back Racking – Balances density and selectivity through a dynamic loading system that accommodates multiple pallets per lane.

Pallet Flow Racking – Incorporates gravity-fed lanes to facilitate FIFO inventory management for date-sensitive products.

Cantilever Racking – Specialized for long or irregularly shaped items that don't conform to standard pallet configurations.

Carton Flow Racks – Optimized for piece picking operations with high SKU counts and variable unit movement.

Automated Storage Systems – Vertical lift modules, carousels, and robotic retrieval systems that maximize both space utilization and picking efficiency.

The selection of appropriate storage media should reflect product characteristics, throughput requirements, and budget constraints.

Material Handling Systems: Enhancing Operational Flow

Material handling equipment selection profoundly impacts warehouse design, influencing aisle width, ceiling height requirements, and overall facility configuration.

Equipment Selection and Integration

The material handling equipment profile must match operational requirements:

Counterbalance Forklifts – Require wider aisles (typically 12-13 feet) but offer versatility for both indoor and outdoor operations.

Reach Trucks – Operate in narrower aisles (8-10 feet) and reach higher storage positions, enabling better space utilization.

Turret Trucks – Facilitate very narrow aisle operations (5-7 feet) by rotating the forks 90 degrees to pick from either side without turning the vehicle.

Order Pickers – Allow operators to elevate to picking positions, essential for operations with high-level case picking requirements.

Pallet Jacks – Manual or powered units that require minimal infrastructure but limit vertical utilization.

Equipment selection directly influences facility design parameters including aisle dimensions, floor specifications, and charging infrastructure requirements.

Conveyor and Sortation Systems

Fixed material handling systems serve as the circulatory system of high-volume operations:

Powered Conveyor Networks – Transport products between operational areas, requiring careful integration with workstations and storage zones.

Sortation Systems – Divert products to appropriate destinations based on barcode scans or RFID readings, necessitating substantial space allocation and sophisticated controls.

Vertical Conveyance – Spiral conveyors, vertical lifts, and incline conveyors connect multiple levels while minimizing footprint requirements.

Merge and Divert Points – Critical junctures where product flows combine or separate, requiring careful placement to prevent bottlenecks.

Fixed handling systems demand early integration into warehouse designs as they significantly impact building structural requirements and operational flow patterns.

Automation and Robotics

Increasingly critical in modern warehouse design, automated systems include:

Automated Guided Vehicles (AGVs) – Self-directed transport units that follow predetermined paths, requiring unobstructed travel lanes and charging infrastructure.

Autonomous Mobile Robots (AMRs) – Flexible robotic platforms that navigate dynamically around obstacles, demanding less fixed infrastructure than traditional AGVs.

Goods-to-Person Systems – Robotic retrieval mechanisms that deliver products to stationary pickers, dramatically reducing travel time while increasing picking accuracy.

Robotic Palletizers/Depalletizers – Automated systems that build or break down pallet loads, requiring specialized end-of-line spaces with safety barriers.

Automated Storage and Retrieval Systems (AS/RS) – Computer-controlled systems that place and retrieve loads from defined storage locations, often requiring specialized building designs to accommodate their height and operational parameters.

Automation implementation demands thorough analysis of product characteristics, throughput requirements, and return on investment calculations.

Safety and Compliance: Creating Secure Operations

Safety considerations must be integrated throughout the warehouse design process, not added as afterthoughts.

Traffic Management Planning

Effective warehouse designs incorporate clear traffic patterns:

Dedicated Travel Lanes – Separate pedestrian pathways from equipment routes to minimize collision risks.

One-Way Traffic Flows – Reduce intersection points where vehicles might encounter each other from multiple directions.

Speed Control Measures – Physical and visual cues that enforce appropriate vehicle speeds in different operational zones.

Crossing Points – Clearly marked intersections with appropriate visibility and warning systems.

Staging Areas – Designated spaces that prevent congestion at critical operational junctures.

Proper traffic management reduces accident risks while simultaneously improving operational flow.

Safety Infrastructure Integration

Physical safety measures must be incorporated into warehouse structures:

Rack Protection Systems – Guards, bollards, and end-of-aisle protectors that prevent damage from material handling equipment impacts.

Fall Protection – Guardrails, safety gates, and harness anchor points for elevated work areas.

Fire Suppression Systems – Sprinklers, fire doors, and specialized extinguishing systems appropriate for stored materials.

Emergency Evacuation Routes – Clearly marked pathways to exits, sized appropriately for the facility population.

Safety Signage – Visual indicators of hazards, protocols, and equipment requirements throughout the facility.

These elements should be planned during initial design phases rather than retrofitted later at higher cost and with potential operational disruption.

Ergonomic Considerations

Human factors significantly influence warehouse productivity and safety:

Picking Height Optimization – Positioning frequent-pick items between knuckle and shoulder height to reduce strain.

Lift-Assist Devices – Mechanical aids that reduce the physical burden of handling heavy or awkward items.

Adjustable Workstations – Flexible packing and processing areas that accommodate different operator heights and preferences.

Flooring Selection – Anti-fatigue surfaces in stationary work areas to reduce operator strain during extended periods of standing.

Lighting Design – Appropriate illumination levels for various tasks, minimizing shadows and reducing eye strain.

Ergonomic design elements reduce injury risks while simultaneously improving productivity and accuracy metrics.

Technology Integration: Enhancing Operational Intelligence

Beyond physical infrastructure, modern warehouse design must accommodate sophisticated technological systems.

Warehouse Management System Infrastructure

The WMS serves as the warehouse's central nervous system:

Server Infrastructure – Dedicated spaces for computing resources with appropriate cooling, power, and security provisions.

Wireless Network Coverage – Comprehensive connectivity throughout the facility, including challenging areas such as freezers or high-racking zones.

Workstation Deployment – Strategically positioned terminals and mobile devices for data entry and retrieval.

Integration Points – Connections with automation systems, material handling equipment, and enterprise software.

The WMS infrastructure must support both current operations and anticipated future needs.

Data Collection and Visibility Tools

Real-time operational intelligence relies on comprehensive data capture:

Scanning Points – Strategically positioned barcode and RFID reading stations throughout product flow paths.

IoT Sensor Networks – Devices monitoring environmental conditions, equipment performance, and inventory status.

Computer Vision Systems – Cameras and image processing technology for automated inspection and verification.

Real-Time Location Systems (RTLS) – Networks tracking the position of assets, equipment, and personnel throughout the facility.

These systems generate the data streams necessary for operational optimization and continuous improvement initiatives.

Analytics and Decision Support Systems

Modern warehouse design should accommodate advanced analytics capabilities:

Digital Twins – Virtual representations of the physical warehouse for simulation and optimization.

Predictive Maintenance Systems – Monitoring tools that anticipate equipment failures before they cause operational disruptions.

Labor Management Systems – Performance tracking and optimization tools that enhance workforce productivity.

Demand Forecasting Integration – Connections between warehouse operations and broader supply chain planning systems.

These analytical capabilities transform operational data into actionable intelligence, driving continuous improvement.

Future-Proofing: Designing for Adaptability

Warehouse facilities represent significant long-term investments, demanding designs that accommodate future operational evolution.

Scalability Provisions

Effective designs anticipate growth requirements:

Expansion Zones – Designated areas for future building extensions with appropriate utility and access planning.

Phased Implementation Areas – Spaces allocated for additional automation or capacity enhancements as volume increases.

Modular Rack Configurations – Systems that can be reconfigured or expanded as storage needs evolve.

Infrastructure Oversizing – Utility services with capacity beyond initial requirements to accommodate future demands.

These provisions allow facilities to grow in capacity without disruptive renovations or operational compromises.

Flexibility Features

Adaptable designs accommodate changing operational requirements:

Reconfigurable Storage Systems – Racking and shelving that can be modified to handle different product profiles.

Multi-Purpose Areas – Spaces that can transition between different operational functions as seasonal demands shift.

Movable Workstations – Processing areas that can be repositioned to optimize workflow as operations evolve.

Demountable Office Space – Administrative areas that can be relocated or resized without major construction.

These flexibility features extend facility lifespan by adapting to changing business requirements.

Sustainability Considerations

Environmental factors increasingly influence warehouse design:

Energy-Efficient Systems – Lighting, HVAC, and equipment selections that minimize energy consumption.

Renewable Energy Integration – Solar panels, wind turbines, or other alternative energy sources that reduce operational costs and environmental impact.

Water Management Systems – Rainwater harvesting, retention ponds, and permeable surfaces that minimize environmental disruption.

Waste Reduction Infrastructure – Recycling systems, compactors, and waste stream separation facilities.

Sustainable design elements not only reduce environmental impact but often deliver substantial operational cost savings over facility lifespans.

Conclusion

Warehouse design represents a complex interplay of spatial, operational, technological, and human factors. The most successful facilities result from thoughtful integration of these elements into coherent systems that balance immediate operational requirements with long-term strategic objectives.

By thoroughly addressing the factors outlined in this guide—space utilization, inventory management, material handling systems, safety protocols, technology integration, and future-proofing provisions—organizations can develop warehouse facilities that deliver sustainable competitive advantage through operational excellence.

In today's dynamic business environment, warehouse design must transcend mere spatial planning to encompass comprehensive operational strategy. The resulting facilities don't simply store products—they accelerate them through supply chains with maximum efficiency, minimum cost, and optimal customer service.

Frequently Asked Questions

Q: What is the optimal ceiling height for modern warehouse facilities?

A: While traditional warehouses often featured 24-30 foot clear heights, modern facilities frequently incorporate 36-40+ foot clearances to maximize vertical space utilization. The optimal height depends on product characteristics, handling equipment capabilities, and fire protection requirements.

Q: How does e-commerce fulfillment influence warehouse design?

A: E-commerce operations typically require more extensive picking areas, greater SKU capacity, specialized packing stations, returns processing zones, and higher levels of automation compared to traditional wholesale distribution facilities.

Q: What role does simulation play in warehouse design?

A: Computer simulation allows designers to test operational concepts before physical implementation, identifying potential bottlenecks, validating capacity assumptions, and optimizing equipment quantities. These virtual prototypes substantially reduce implementation risks.

Q: How should seasonal fluctuations influence warehouse design?

A: Facilities with significant seasonality should incorporate flexible spaces that can transition between storage and processing functions, temporary staffing accommodations, modular equipment that scales with volume, and staging areas for seasonal inventory buildups.

Q: What are the most common mistakes in warehouse design?

A: Frequent errors include insufficient dock capacity, inadequate staging areas, inflexible storage systems, poor traffic flow planning, limited expansion provisions, and failure to anticipate technological integration requirements. Comprehensive planning processes help avoid these pitfalls.

Do you need more information?

Our team of experts will be happy to help you with any questions you may have.

More information